Mold accessories

Product classification

European standard pneumatic cylinder, air valve, pneumatic push pin exhaust valve, air nozzle,Pneumatic Cylinder for Mold Automation

Keyword:

Pneumatic Cylinder for Mold Automation

Classification:

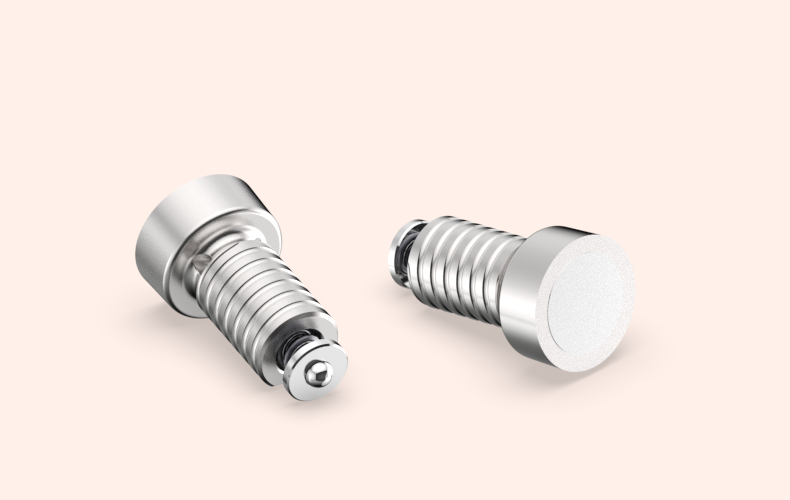

In the ever - evolving world of manufacturing, the pneumatic cylinder for mold automation has emerged as a crucial component that is transforming the way molds are operated.The pneumatic cylinder is specifically designed to meet the unique demands of mold automation. It offers a reliable and efficient means of powering the movement within the mold making process. With its precise engineering, it provides accurate and repeatable motion, which is essential for creating high quality molds.

One of the key advantages of this pneumatic cylinder is its speed. It can quickly actuate the various parts of the mold, significantly reducing cycle times. In a highly competitive manufacturing environment, where time is of the essence, this ability to accelerate the mold - making process gives manufacturers a distinct edge. It allows for increased production output without sacrificing the integrity of the molds.

The force generated by the pneumatic cylinder is also highly controllable. Manufacturers can adjust the pressure within the cylinder to exert the exact amount of force required for different mold - related tasks. This precision in force application is vital for tasks such as ejecting molded parts from the die. It ensures that the parts are removed without damage, improving the overall yield of the production process.

In terms of durability, the pneumatic cylinder for mold automation is built to last. It is constructed using high - quality materials that can withstand the harsh conditions often present in a manufacturing environment. These cylinders are resistant to corrosion, wear, and tear, which means that they require less frequent replacement, reducing maintenance costs in the long run.

Another notable feature is the compact size of these pneumatic cylinders. Despite their powerful performance, they are designed to fit into tight spaces within the mold automation setup. This space - saving characteristic is especially beneficial for modern manufacturing facilities where space is often at a premium.

The integration of the pneumatic cylinder into existing mold automation systems is seamless. It can be easily connected to other components such as valves, sensors, and controllers. This compatibility allows manufacturers to upgrade their existing mold automation lines without major overhauls.

Furthermore, the pneumatic cylinder for mold automation is environmentally friendly. Pneumatic systems are known for their energy - efficiency, as they use compressed air as the power source. This not only reduces the energy consumption of the manufacturing process but also contributes to the overall sustainability goals of the industry.

In conclusion, the pneumatic cylinder for mold automation is a game - changer in the molding industry. Its combination of speed, precision, durability, compactness, and environmental - friendliness makes it an indispensable tool for manufacturers looking to enhance their mold - making processes and stay competitive in the global market.

Previous Page

Demand Message

Please contact us in time to get your exclusive offer