Mold accessories

Product classification

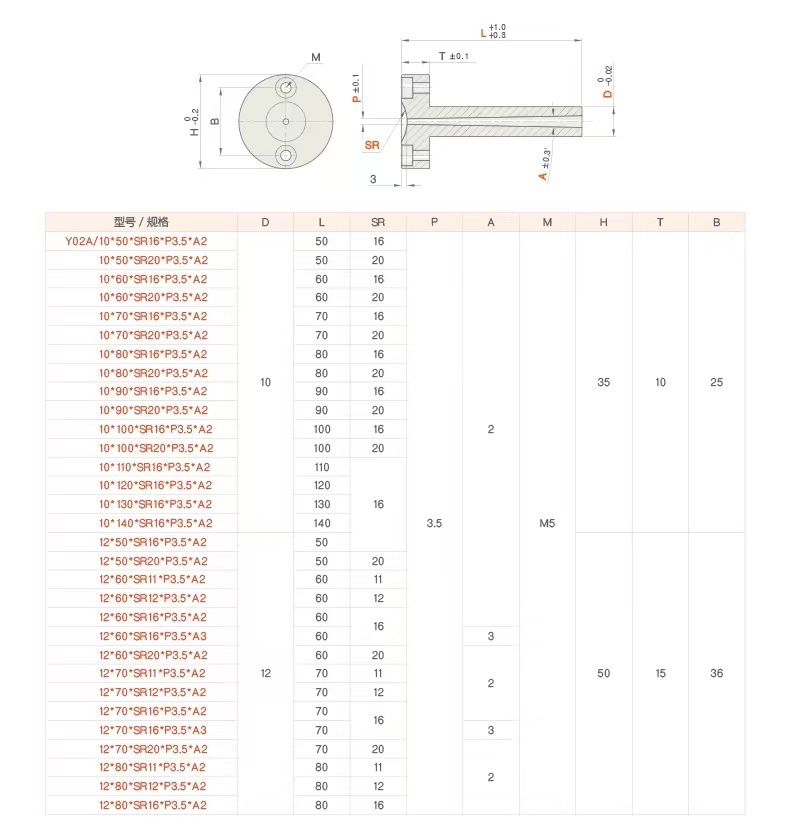

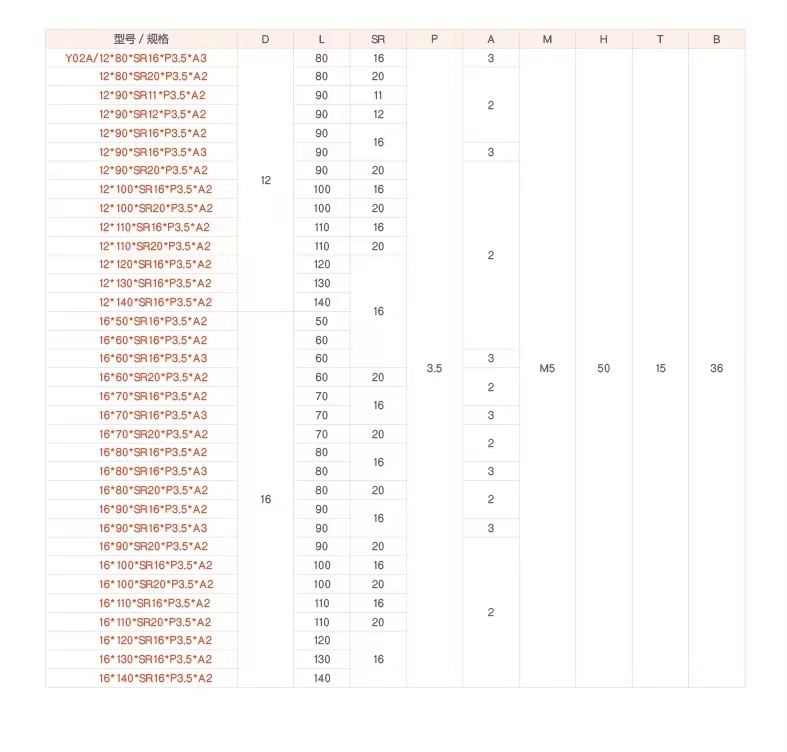

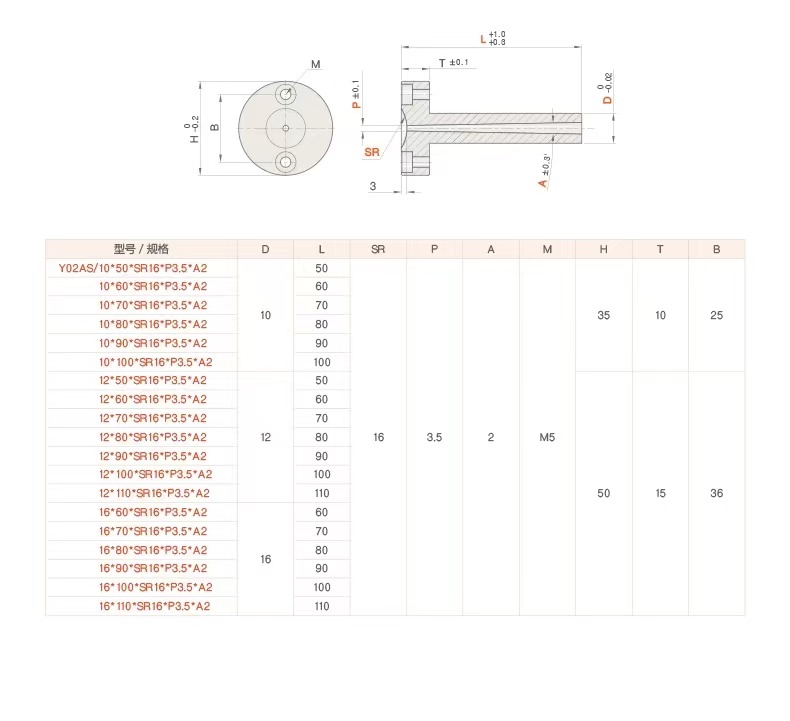

Type A nozzle, sprue bushing, liner, feed throat,Injection Molding Sprue

Keyword:

Mold accessories

Injection Molding Sprue

Mold Positioning Block

Classification:

In the world of injection molding, the injection molding sprue plays a vital and often overlooked role.The injection molding sprue is the conduit through which molten plastic is transferred from the injection unit to the mold cavity. It serves as the initial pathway for the plastic material, ensuring a smooth and consistent flow into the mold.

One of the key aspects of a well - designed injection molding sprue is its diameter. The proper diameter is crucial as it directly affects the flow rate of the molten plastic. If the sprue diameter is too small, it can lead to increased pressure requirements, which may result in incomplete filling of the mold or even damage to the injection molding machine. On the other hand, if the diameter is too large, it can cause issues such as excessive material waste and longer cooling times.

Material selection for the injection molding sprue is also of great importance. High - quality, heat - resistant materials are typically used to withstand the high temperatures of the molten plastic. This ensures that the sprue does not deform or break during the injection process, which could lead to costly production interruptions.

Recent advancements in injection molding sprue technology have focused on improving its efficiency and reducing production costs. For example, some manufacturers are now using innovative coatings on the sprue surface. These coatings can reduce friction, allowing for a more even flow of the molten plastic. This not only improves the quality of the molded parts but also reduces the energy consumption of the injection molding process.

In addition, new designs of injection molding sprues are being developed to optimize the demolding process. A well - designed sprue can be easily removed from the molded part without causing any damage, which is especially important for high - precision and delicate components.

The injection molding sprue also has an impact on the overall cycle time of the injection molding process. By ensuring a rapid and efficient transfer of the molten plastic, the sprue can help to reduce the time between successive injections, increasing the productivity of the molding operation.

In conclusion, the injection molding sprue is a small but essential part of the injection molding process. Continued research and development in this area are likely to bring further improvements in the quality, cost - effectiveness, and efficiency of injection molding operations across various industries.

Previous Page

Demand Message

Please contact us in time to get your exclusive offer